Product Center

Coating Die Series

Hollow lattice plate die series

amination Film Die Series

Sheet Die Series

Cast Film Die Series

Coating Die Series

Sheet Die Series

Multi-layer co-extrusion Lamination feed block

In-mold multi-layer coextrusion

Rack Plate For Extrusion Machinery

Melt metering pump

Quick screen changer

Mesh free filter

Perovskite coating series

Hot melt adhesive coating series

Photoresist (lithium battery coating series)

Scraper (slit, comma) series

Adhesive coated die head series

Automatic Die Head - Rainbow Film

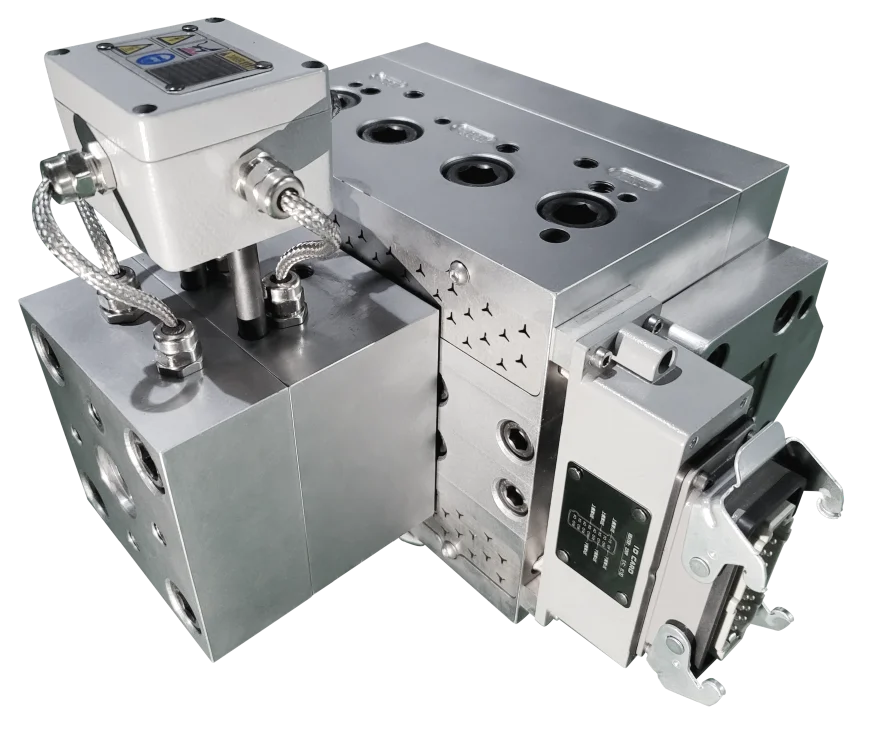

In-mold multi-layer coextrusion

In-mold multi-layer coextrusion

Product Description

It is suitable for materials with different melting points to solve the temperature difference of different melting points, control each detail and improve the uniformity of compounding through layered (two-layer,three-layer and five-layer) die cavity coextrusion compounding, independent temperature control of each die cavity, and thermal insulation devices in each layer.

Technical Characteristics

multi layer materials can obtain more layers of product structure through composite distributor and composite mold cavity;

the proportion and thickness of each layer of materials can be adjusted arbitrarily through the composite mold cavity;

customize the special flow channel according to different raw materials to obtain a uniform flow surface without resistance;

portable push-pullstructure can quickly adjust the dielip gap to quickly adjust and optimize the transverse uniformity of thickness;

equipped with flow regulation device to make the material regulation range larger, so as to quickly adjust and optimize the transverse uniformity of product thickness;

various internal or external blocking width adjustment devices can be selected to realize on-line rapid adjustment;

grade 12.9 high strength bolts shall be used for allfasteners;

the heating element adopts high-quality and durable brand stainless steel heating rod.